The Stainless-Steel Flap gate is a robust, heavy-duty waist-height turnstile designed to efficiently manage crowd flow and facilitate per-person payment collection. This reliable turnstile supports a throughput of 45 passengers per minute, ensuring swift and smooth access. Additionally, it features a dependable emergency mode and a heavy-duty mechanism, guaranteeing operational reliability in various scenarios. Its seamless integration with fare validators enhances its functionality, making it an ideal choice for diverse access control applications.

| Passage Control Module | Smart connected controller which controls the aisle area and safety and drives the motor |

|---|---|

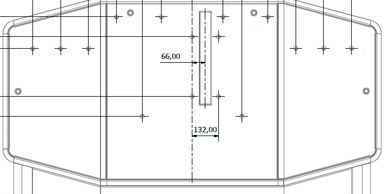

| Passage width | Standard passage width is 550 mm and wide width is 900 mm |

| Photoelectric Sensors | 16 photoelectric sensors to recognize intrusion, Tailgating, piggybacking, Wrong way direction and child passage |

| Emergency mode | Two separated emergency inputs |

| Tamper Switch | One Tamper switch on each door |

| Temperature sensor | In-built high temperature protection circuit |

| Serial Connection | One external RS232 port |

| Gate End Display | Two 120x120 mm gate end display |

| Buzzer | One alarm buzzer |

| Passage authorization | Two separated dry contact for passage authorization Software passage authorization over serial connection |

| Inputs/Outputs | 16 opto-couple rated at 24 VDC, protected against invention & over voltage 6 relay outputs providing 24 VDC - 50mA output insulated from general ground One static relay output providing 24V - 1A electrically insulated from general ground 6 spare inputs and 6 spare outputs |

| Power Supply | 220VAC Power supply (+/- 10%) |

| Physical Characteristics | Dimensions: 1000 (H) X 1900 (w) X 300 (D) [mm] |

| Mean Cycle Between Failure | 4 million (5 million if normally open) |

| Mean Time To Repair | Less than 30 minutes |

| Working Temperature | '-5 OC to +50 OC and 95% humidity |

| Passenger Safety | Four sensor install near moving obstacle to prevent closing when a passenger is standing between the flaps. The thickness and the density of the polyurethane allow shock absorption and reduction of the mass in movement. An electromagnetic device limits the closing force to 250 N. In case of a main power failure emergency mode, the obstacle opens immediately by means of spring and gravity force. |

| CPU | Quad Core Cortex-A9, with dynamic frequency scaling up to 1.4GHz |

|---|---|

| RAM | 1GB 32bit DDR3 |

| Gate End Display | Two 12×12 cm gate end display |

| Passage authorization | Two separated dry contact for passage authorization, Software passage authorization over serial port |

| Flash Memory | 8GB onboard eMMC memory |

| Operating System | Linux Ubuntu-core, Android 4.4 |

| Buzzer | 106 dB in 10cm, 3.5 KHz frequency |

| Display | 5.0-inch (Diagonal) TFT LCD 640×480 |

| Photoelectric Sensors | 16 photoelectric sensors to recognize Intrusion, Tailgating, Piggybacking, Wrong way direction and Child passage |

| Digital Inputs/Outputs | 4 spare inputs and 4 spare outputs |

| Power supply | 90-264VAC power supply |

| Passage Width | Standard passage width is 550/600mm and Wide passage width is 900mm |

|---|---|

| Tamper Switch | One tamper switch on each door |

| Physical Characteristics | Dimensions: 1000 (H) x 1900 (W) x 300 (D) |

| Working Temperature | -10 C to +60 C |

| Passenger Safety | - Four sensors install near moving obstacle to prevent closing when a passenger is standing between the flaps - The thickness and the density of the polyurethane allow shock absorption and reduction of the mass in movement. - An electromagnetic device limits the closing force to 280 N - In case of a main power failure or emergency mode, the flap barrier opens immediately |

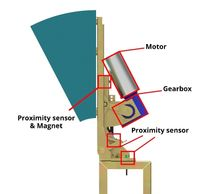

The flap gate mechanism has two proximity sensors to detect whether the gate is open. There is also a magnet and a proximity sensor which manage the emergency mode. If the gate should go to emergency mode (or the power failure) the magnet disables and gate will be open immediately using gravity force.

Two motorized obstacles are located halfway through the aisle (one for each gate) and slide perpendicularly to the direction of transit.

The obstacle is approximately triangular in Shape and composed of one element (single Flap Type) or two elements (telescopic Flap Type). Each element is made of an internal stainless-steel structure coated with energy-absorbent integral polyurethane.

The movement of the Flaps ensures a smooth operation without vibration. When the aisle is open, the gate barriers are fully retracted into the cabinet so that the aisle is entirely clear and free of any obstruction.

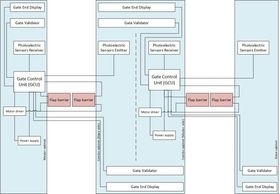

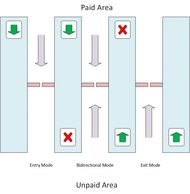

Gate cabinets can be configured in three modes:

Master side of the gate controls all gate functionalities including sensors data processing, motor controlling and etc. Slave side is complemented of master side to provide the gate functionalities.

Combo cabinets are using in the middle of gate array and including one master side and one slave side.

Gates can be configured in an array mode. There are these 3 configuration modes:

An Industrial Rail-Mount Power Supply is employed as the source of the power.

The NDR-480 is an economical slim 480watt (24V-20Amp) DIN rail power supply series. It adopts the full range AC input from 90VAC to 264VAC and conforms to EN61000-3-2, the norm the European Union regulates for harmonic current.

Features: